News

New Look Prop Shafts for LandCruisers in Mining

When your fleet is clocking up serious hours on site, driveline reliability isn’t a “nice to have.” It’s a necessity. For mining operations across Australia, few vehicles cop a harder life than a Toyota LandCruiser 70 Series.

In mining operations, there’s often two competing priorities when it comes to maintenance. The first priority is reducing downtime with high quality parts and effective maintenance programs. The second priority is reducing the operating expenses and unit costs associated with spare parts. You can see how these two priorities clash, as they’re almost polar opposites when it comes to a maintenance strategy.

We decided that because prop shafts are such a critical part when it comes to Landcruisers, we would design and manufacture two different parts which speak to the two different priorities.

- a high-spec upgrade that lasts longer

- a cost-effective alternative to reduce unit cost and operating expenses

Keep reading for more information about those two new products, and also some general context about prop shafts in a mining context.

What a Prop Shaft Does and Why It Matters

A prop shaft (short for “propeller shaft”) transfers torque from the gearbox to the differentials. It’s the key link between the engine and the wheels.

On a 4WD like a LandCruiser, there are two prop shafts: one at the front and one at the rear. The front prop shaft plays a critical role in traction and stability, especially on uneven terrain. If it fails, the vehicle is down and productivity takes a hit.

The Difference Between Front and Rear Prop Shafts

Both front and rear prop shafts transfer drive, but the way they work and the punishment they take on a mine site is different.

- Rear prop shafts usually carry more torque and are generally more robust.

- Front prop shafts experience more articulation and more exposure to dust, mud and water.

On mining sites, the front prop shaft is often the first driveline component to wear out, which is why having a reliable unit matters.

Why Prop Shafts Fail on Mine Sites

Mining environments are tough on vehicles, especially driveline parts like prop shafts. Here are the main reasons they fail:

- Contamination: Fine dust, water, mud and debris work their way into the spline and universal joints, speeding up wear.

- Harsh terrain: Constant articulation on rough ground puts extra stress on joints, bearings and splines.

- Maintenance gaps: When grease points are hard to reach, they’re often skipped. Over time, dry joints lead to vibration and eventual failure.

- High utilisation: Mine site vehicles run long hours with little downtime, which compounds wear.

Every failure costs more than the price of the part. It affects uptime, productivity and overall maintenance budgets.

How to Reduce Prop Shaft Maintenance Costs

Upgrading to the right prop shaft can make a big difference to your operation. With the right spec part, you can:

- Extend service intervals

- Reduce unplanned downtime

- Lower total cost of ownership

- Improve fitter efficiency on site

That’s where our two new TAKEO front prop shafts for LandCruisers come in.

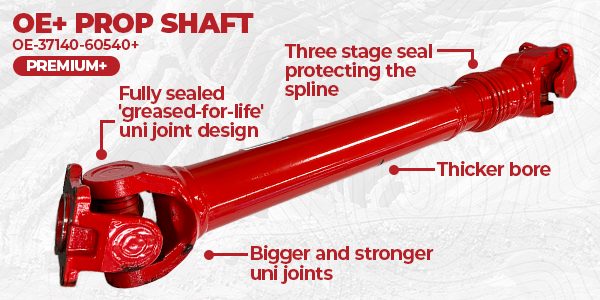

TAKEO PREMIUM+ Front Prop Shaft

For fleets that want to extend component life and reduce downtime.

The TAKEO PREMIUM+ Front Prop Shaft is a high-spec unit built for maximum durability in harsh mining environments. It is engineered to outlast the OEM unit and deliver lower maintenance requirements over time.

Key Features:

- Thicker bore tube for improved strength

- Upgraded universal joints for heavy-duty performance

- Concertina boot covering the spline for extra protection against contaminants

- Sealed-for-life universal joints with pre-packed grease

The sealed-for-life design is the same concept used in heavy diesel machinery. By removing the need for greasing, it eliminates one of the most common failure points in extreme conditions – seal ingress. No grease point at all means nothing in, and nothing out. Since the universal joints are completely sealed to the outside environment, the risk of contamination is decreased to zero.

While this fully sealed unit might be overkill in other applications or industries, in mining it can mean double the lifespan. The conditions that mining vehicles operate in are some of the most extreme, with huge exposure to contaminants such as dust, dirt, mud, salt water and more. Now combine all those contaminants with the shock damage of uneven terrain, hard rock tracks and debris damage underneath the vehicle, and you can see why ingress would present a problem.

This unit is a Premium+ upgrade, which comes with a premium price. But it’s important to remember the costs associated with frequent downtime and maintenance. By extending lifespan with a premium part, you’re increasing the service intervals, which saves valuable labour hours and keeps the vehicle in the field as a productive asset.

For sites where reliability and uptime are the priority, this is the smart choice.

TAKEO PURE Front Prop Shaft

For fleets focused on cost savings and easy maintenance.

The TAKEO PURE Front Prop Shaft is a practical, cost-effective option for operations that want a solid part without paying a premium price.

Key Features:

- Accessible grease nipples on the end cap of the universal joints so fitters can easily service them

- Concertina boot over the spline to protect against contaminants, which OEM shafts do not offer

- Strong, reliable construction at a lower cost

Because the grease points are easy to reach, routine maintenance is far more likely to be done properly. This keeps the shaft in good working order and helps reduce unexpected failures. While we can’t guarantee this unit will last longer than the genuine Toyota prop shaft, the increased accessibility to the grease points makes it easier to maintain, and therefore helps the workshop run it’s scheduled maintenance more efficiently.

Some mining operations prefer a low operational expense model when it comes to their assets and maintenance. This is the part for those sites. We re-engineered this part based on the OEM unit, to make sure quality and fitment wasn’t sacrificed. If your site has never really had a problem with prop shafts, or your simply looking to reduce operational expenses on paper – this is the part for you.

Developed and Tested for the Mining Industry

Autoline is more than a parts distributor. Research and development is a major part of what we do. We work closely with mining operators to design and improve components that solve real-world problems on site.

Our TAKEO front prop shafts are currently being trialled in active mining fleets to collect performance data and refine the product even further.

A Full Range of LandCruiser Parts

The TAKEO range includes much more than just front prop shafts. Our range covers driveline, suspension, brakes, steering, doors and other critical components. All parts are designed to withstand the punishment of Australian mining conditions. We have up to one thousand stocked lines for the Landcruiser and Hilux, plus custom built kits specifically for vehicles in mining operations.

You can download the TAKEO critical spares catalogue for free – click here.

If your operation is ready to reduce maintenance headaches and keep LandCruisers working harder for longer, get in touch with our team today.

TAKEO Front Prop Shafts — Built for the Mine. Available Now.

Contact Autoline to order or learn more.

GET IN TOUCH

We’re open Monday to

Friday, 7.30am – 5pm.

Phone: 1300 310 310

Fax: +61 (8) 9351 5470

Email: [email protected]

Got a question or need a quote?

Use this form and we’ll get right back to you.

My Account

My Account